How Do Hydraulic Cylinders Work in an Aerial Work Platform?

Author:

Release time:2025.07.05

Hydraulic cylinders are essential components in aerial work platforms (AWPs), providing the linear motion required for lifting, lowering, extending, and rotating. They operate by converting hydraulic energy (fluid pressure) into mechanical force.

Basic Working Principle

Hydraulic cylinders function based on fluid pressure:

- Lifting (Upward Movement): A hydraulic pump delivers pressurized oil into one side of the cylinder (usually the bottom or piston end). The pressure forces the piston to extend, lifting the platform or boom.

- Lowering (Downward Movement): Control valves release oil from the cylinder, usually to a tank. The platform lowers under its own weight or controlled fluid return.

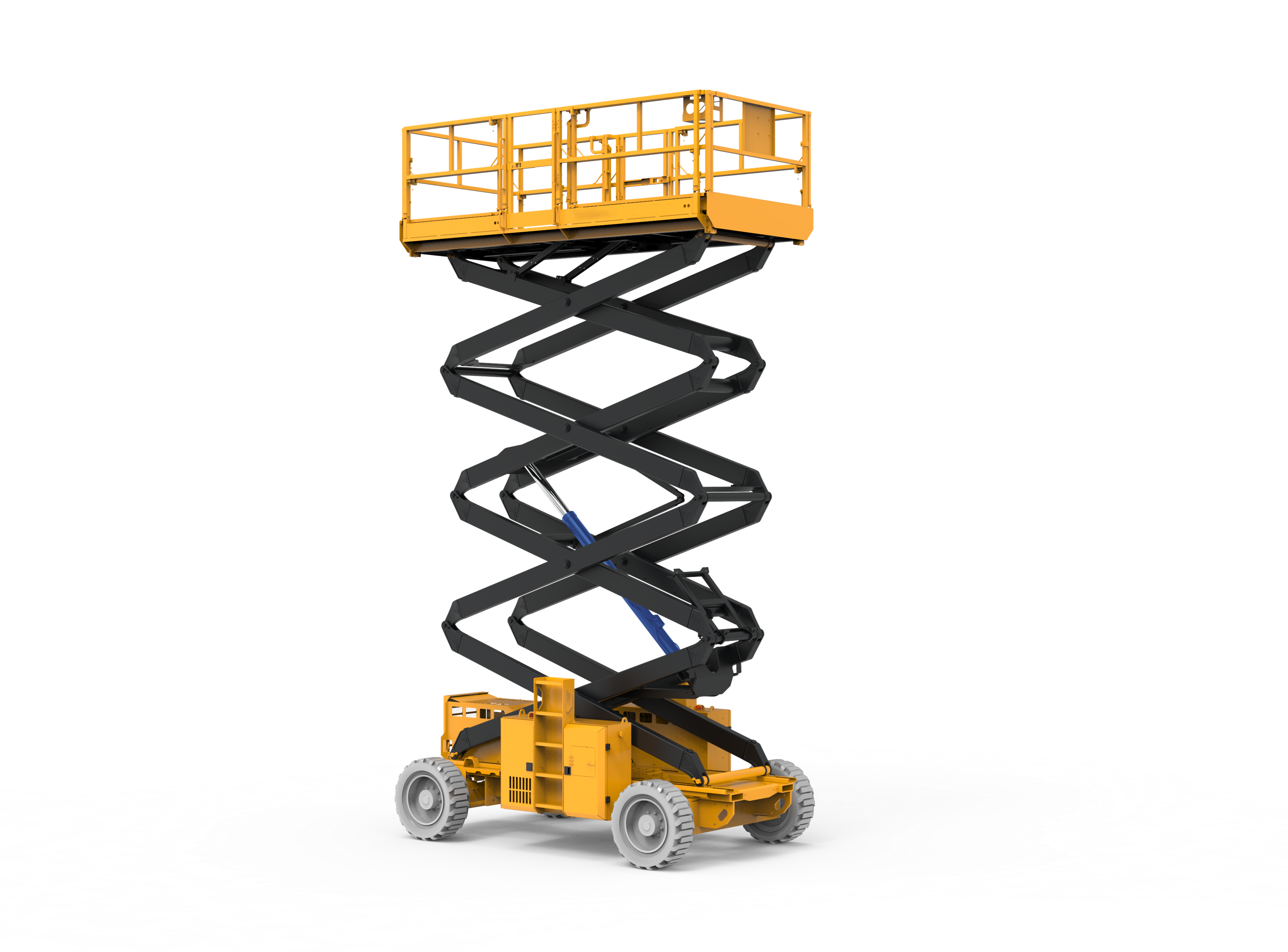

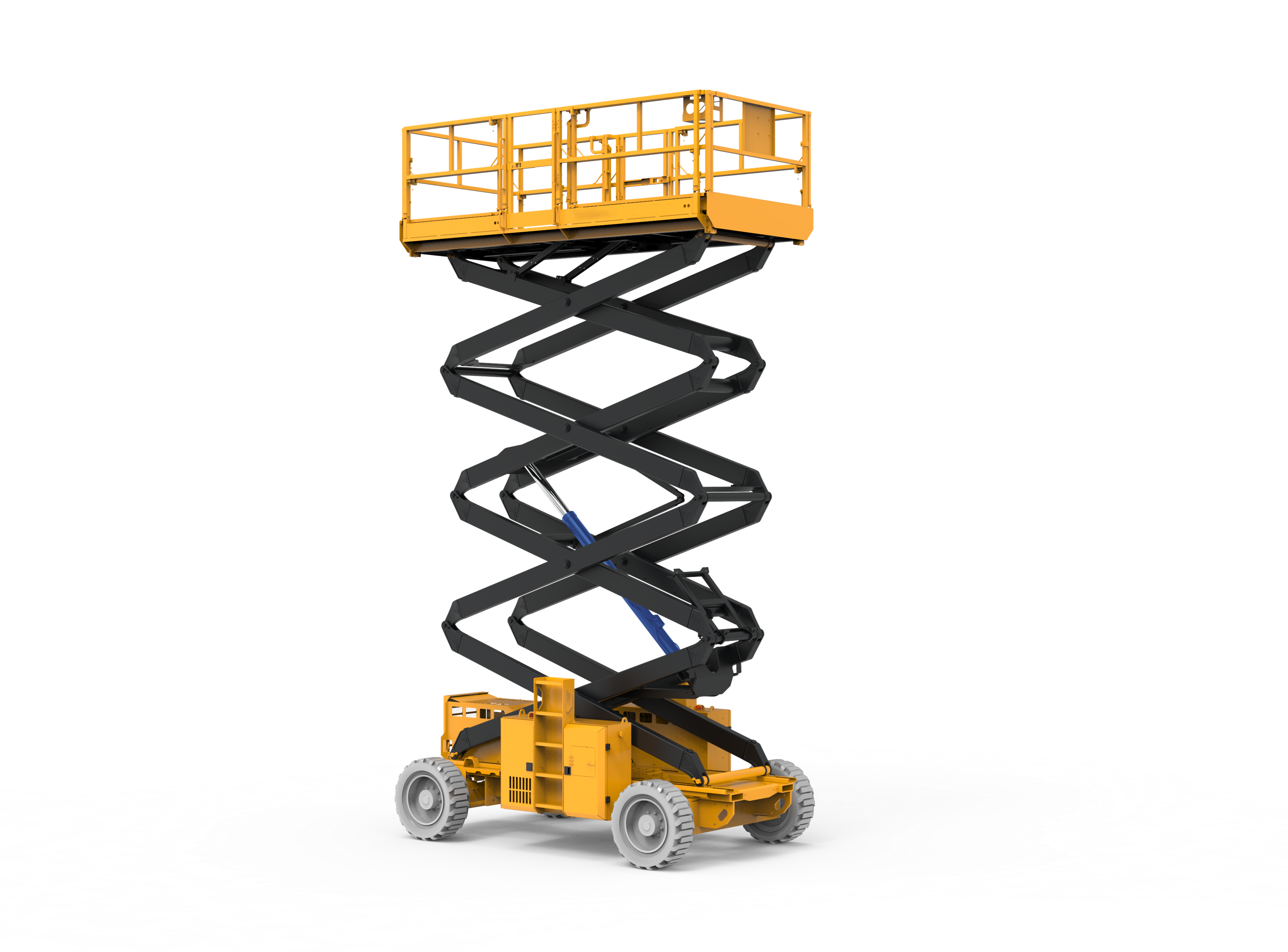

Application in Different Types of AWPs

- Cylinder Placement: Mounted between the base and the scissor arms.

- Function: Pushes the scissor mechanism open to raise the platform.

- Control: Uses throttle or proportional valves to adjust speed smoothly.

2. Boom Lift (Articulating or Telescopic)

- Cylinder Types: Double-acting or telescopic hydraulic cylinders.

- Function: Control boom lifting and extension. Allow multi-directional movement and higher reach.

- Mounted On: Main boom, secondary boom, and rotating base.

3. Mast Lift

- Cylinder Type: Often uses telescopic cylinders or chain-driven hydraulic lifts.

- Application: Compact and efficient for indoor operations.

- Cylinder Use: A combination of lift cylinders, outrigger cylinders, and rotation cylinders.

- Purpose: Controls lifting, stabilization, and rotation of the boom.

Control and Safety Features

Hydraulic Control System includes:

- Hydraulic Pump Unit: Provides the pressure source.

- Directional Control Valves: Direct the fluid to move the cylinder in or out.

- Sensors: Monitor position and pressure.

- PLC or Microcontroller: Manages movement coordination and safety logic.

Safety Features:

- Burst Valves: Prevent sudden drop in case of hose failure.

- Flow Control/Buffer Valves: Regulate speed and prevent jerky movement.

- Counterbalance Valves: Hold the load in place when valves are closed.

Summary Table

| Function | How It's Achieved |

|---|

| Lifting | Hydraulic fluid pushes the piston to raise the platform |

| Lowering | Fluid is released from the cylinder, platform lowers |

| Extension | Telescopic cylinders extend the boom |

| Rotation | Rotational cylinders turn the boom or platform

|

Conclusion

Hydraulic cylinders are the driving force behind the smooth, powerful, and precise movement of aerial work platforms. Whether it’s lifting a scissor mechanism, extending a telescopic boom, or stabilizing a truck-mounted unit, these cylinders transform fluid power into reliable motion. Understanding how they work not only helps in equipment selection and maintenance but also ensures safer and more efficient operation at height. As aerial access technology evolves, hydraulic systems continue to play a vital role in supporting productivity, safety, and versatility across industries.