Hydraulic cylinder force calculation is a fundamental step in designing and selecting cylinders for industrial machinery, construction equipment, and automation systems. Understanding how piston diameter, rod diameter, pressure, and flow rate affect force helps engineers size cylinders accurately and avoid performance issues in hydraulic systems.

This guide explains the formulas, step-by-step calculation methods, and real-world examples for hydraulic cylinder force.

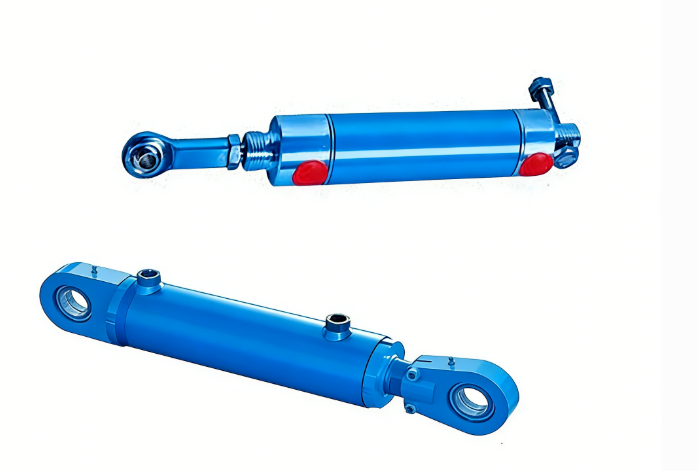

Hydraulic cylinder force is the pushing or pulling force generated when pressurized hydraulic fluid acts on the piston surface inside the cylinder. The force produced depends on the piston diameter, hydraulic pressure, and rod diameter during extension or retraction.

The piston diameter determines the effective area exposed to hydraulic pressure. A larger piston diameter increases the force produced.

The rod diameter reduces the effective area during retraction, which lowers the pulling force compared to extension force.

Pressure in the hydraulic system is usually measured in PSI or bar. Higher pressure increases cylinder force.

Flow rate does not change the force directly but affects cylinder speed. Higher flow rate results in faster cylinder movement.

Force (N) = Pressure (Pa) × Piston Area (m²)

Piston Area = π × (Piston Diameter ÷ 2)²

Force (N) = Pressure × (Piston Area − Rod Area)

Rod Area = π × (Rod Diameter ÷ 2)²

Measure the piston diameter and rod diameter in millimeters or inches.

Convert measurements into meters (for SI) or inches (for imperial calculations).

Use the piston diameter to calculate the piston area.

Use the rod diameter to calculate the rod area for retraction force calculations.

Multiply the effective area by system pressure to calculate the hydraulic cylinder force.

Given:

Step 1: Calculate Piston Area Area = π × (0.1 ÷ 2)² = 0.00785 m²

Step 2: Calculate Rod Area Rod Area = π × (0.04 ÷ 2)² = 0.00126 m²

Step 3: Extension Force Force = 200 bar × 10⁵ Pa/bar × 0.00785 ≈ 157,000 N

Step 4: Retraction Force Force = 200 × 10⁵ × (0.00785 − 0.00126) ≈ 131,800 N

Where:

Flow rate affects how fast the piston moves but does not change the force produced. Cylinder speed is calculated using:

Speed = Flow Rate ÷ Effective Area

Higher flow rate means faster extension and retraction in hydraulic systems.

Hydraulic force calculations are used in:

Multiply hydraulic pressure by the effective piston area. Subtract rod area for retraction force calculations.

Yes. Rod diameter reduces the effective area during retraction, resulting in lower pulling force.

Flow rate affects speed, not force. Pressure and piston area determine the force produced.

Use a hydraulic cylinder force calculator or apply the basic formulas using piston diameter, rod diameter, and pressure values.

A larger piston diameter increases the effective area, which increases hydraulic cylinder force.

Calculating hydraulic cylinder force requires understanding piston diameter, rod diameter, hydraulic pressure, and flow rate. By using standard calculator formulas and step-by-step methods, engineers can design hydraulic systems with accurate force output for specific applications.

This approach helps ensure reliable hydraulic cylinder performance across industrial and mobile equipment environments.