Hydraulic cylinders are widely used in industrial equipment, construction machinery, and agricultural systems to generate linear motion. Understanding the parts of a hydraulic cylinder and how they work helps engineers, buyers, and maintenance teams ensure reliable cylinder operation and long service life.

This guide explains the components of a hydraulic cylinder, their functions, common issues, and maintenance tips.

Hydraulic cylinders are mechanical actuators that convert pressurized hydraulic fluid into linear force and motion. They are essential components in a hydraulic system, enabling machines to lift, push, pull, and position loads with precision.

Hydraulic cylinders operate based on fluid pressure. When hydraulic fluid enters the cylinder, pressure builds inside the chamber and moves the piston.

This process is used in both single acting and double acting cylinder designs.

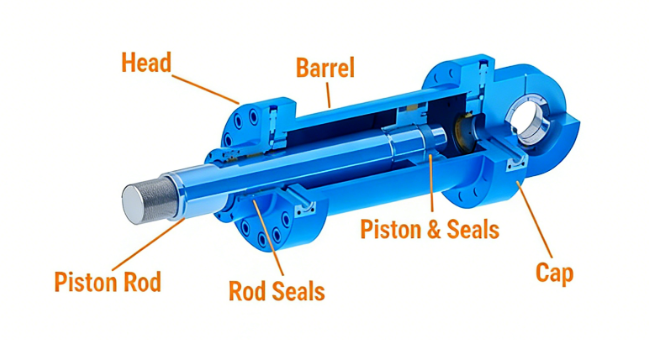

Understanding the parts of a hydraulic cylinder helps with design selection and maintenance.

The cylinder barrel is the main body that houses the piston and hydraulic fluid.

Functions:

Cylinder barrels are typically made from honed steel for durability.

The piston and piston rod convert hydraulic pressure into mechanical motion.

Functions:

The cylinder head is located at the rod end of the cylinder.

Functions:

Rod seals are used to prevent fluid leakage and keep contaminants out.

Functions:

These components seal the piston and guide it inside the barrel.

Functions:

Ports allow hydraulic fluid to enter and exit the cylinder. End caps close the barrel and provide mounting points.

Functions:

Both designs use similar internal components, but port configuration and sealing systems differ.

Hydraulic cylinders rely on seals and precision machining to maintain pressure.

These components ensure efficient cylinder operation and reduce leakage.

Over time, hydraulic cylinder components experience wear and tear due to pressure, friction, and environmental conditions.

Regular inspection helps detect early signs of damage.

Proper maintenance and repair ensure long service life and reliable performance.

Professional hydraulic cylinder repair services can restore performance and extend cylinder lifespan.

Hydraulic cylinders and their components are used in:

The main parts include the cylinder barrel, piston, piston rod, cylinder head, seals, end caps, and ports.

The piston converts hydraulic pressure into motion, and the piston rod transfers the force to external equipment.

Rod seals prevent fluid leakage and protect internal components from contaminants.

The cylinder head supports the piston rod, houses seals, and maintains alignment.

Hydraulic cylinders maintain pressure through precision machining, high-quality seals, and controlled fluid flow.

Repair is needed when there is leakage, reduced force, scoring on the rod or barrel, or abnormal noise during operation.

Hydraulic cylinder parts work together to convert hydraulic pressure into controlled linear motion. Understanding the components of a hydraulic cylinder, sealing systems, and maintenance requirements helps users improve performance and reduce downtime.