As the global transition toward clean energy accelerates, wind energy has become one of the most important renewable energy application sectors worldwide. From onshore wind farms to offshore wind power plants, modern wind turbines rely on advanced mechanical and hydraulic technologies to ensure safe, stable, and efficient operation.

Among these technologies, Hydraulic cylinders for wind power are a core component of wind turbine hydraulic systems, providing precise motion control, load handling capability, and stable performance under extreme operating conditions.

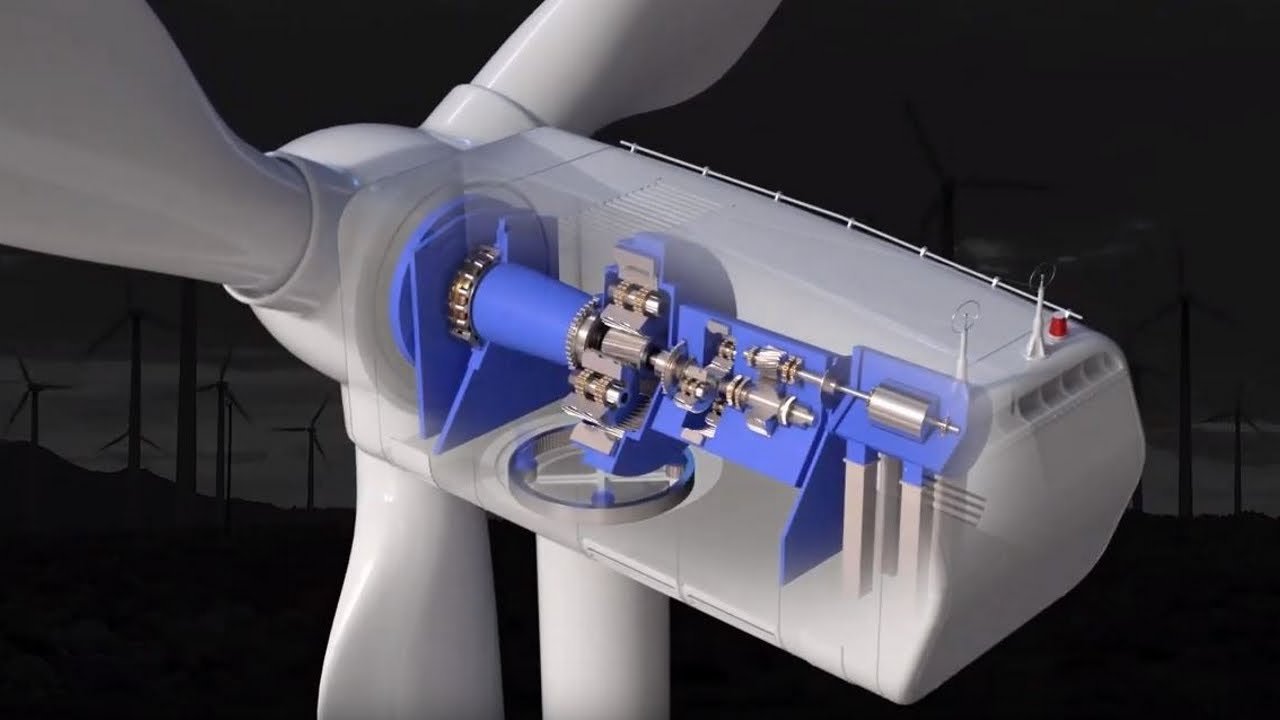

A modern wind turbine is a complex system designed to convert wind into electrical energy with maximum efficiency. While electrical and electronic components control power generation, the hydraulic system is essential for mechanical movement, positioning, and safety functions.

Hydraulic cylinders are widely used to:

These functions ensure turbines operate safely, efficiently, and reliably across varying wind speeds.

Pitch systems adjust the angle of turbine blades to optimize power output and protect the turbine during extreme weather. Custom hydraulic cylinders used in pitch systems must deliver precise motion control, fast response, and long service life.

Key requirements include:

Yaw systems rotate the nacelle so the wind turbine always faces the wind direction. Hydraulic cylinders in yaw systems must handle heavy loads while maintaining smooth and controlled motion to ensure turbines operate efficiently.

Hydraulic cylinders are also used in braking systems to secure the turbine during maintenance or emergency shutdowns. Safety is a key design priority in wind energy applications, particularly in large-scale power plants where unplanned downtime leads to significant operational and financial losses.

Wind turbines are designed for decades of operation. Therefore, high quality materials and robust structural design are essential for hydraulic cylinders used in wind power applications. Components must withstand:

To maximize energy output, hydraulic systems must be efficient and reliable. Low internal friction, optimized sealing, and precise manufacturing help reduce energy losses and maintenance requirements over the turbine’s lifecycle.

Standard industrial cylinders often fail to meet the unique demands of wind energy. Custom hydraulic cylinders are designed according to specific turbine models, load conditions, and installation requirements, ensuring optimal compatibility with wind turbine hydraulic systems.

Customization may include:

Wind power plays a vital role alongside other renewable energy sources such as solar panel systems. Together, wind and solar technologies support a diversified and sustainable energy mix that reduces reliance on fossil fuels and lowers carbon emissions.

In modern renewable power plants, wind energy applications are increasingly integrated with smart grids and energy storage systems, which places higher demands on the reliability and precision of hydraulic components.

As turbines grow larger and more powerful, mechanical loads increase significantly. Hydraulic cylinders ensure that turbines operate safely under these conditions while maintaining precise control over moving components.

Well-designed hydraulic solutions contribute to:

For manufacturers and operators, selecting a supplier with experience in wind energy applications is essential. A reliable partner understands industry standards, long-term performance expectations, and the need for precision engineering in renewable energy systems.

Working with a professional manufacturer ensures that hydraulic cylinders meet the demanding requirements of modern wind power projects.

Hydraulic cylinders are used in pitch systems, yaw systems, braking mechanisms, and safety systems to control movement and ensure stable operation of wind turbines.

Each wind turbine model has unique load, space, and performance requirements. Custom hydraulic cylinders ensure proper integration, long service life, and reliable performance.

Hydraulic systems provide precise control of turbine blades and nacelle positioning, allowing turbines operate at optimal angles and adapt to changing wind conditions.

Yes. Hydraulic cylinders are used in both onshore and offshore wind power plants, with offshore applications requiring additional corrosion resistance and durability.

Wind energy is one of the most mature and scalable forms of clean energy. Along with solar panel systems, it forms a key foundation of global renewable energy development.

As the demand for clean energy continues to grow, wind power remains a cornerstone of global renewable energy strategies. From turbine blades to safety systems, hydraulic cylinders for wind power are essential components that ensure turbines operate safely, efficiently, and reliably.

Through advanced design, high quality manufacturing, and customized solutions, hydraulic cylinders support the long-term success of wind energy applications and the sustainable future of renewable power plants.