Hydraulic cylinders are widely used in industrial machinery, construction equipment, and agricultural systems to generate linear force and motion. Among the most common designs are single acting cylinders and double acting cylinder types.

Understanding their differences helps engineers, buyers, and OEM manufacturers select the right solution for specific applications and operating conditions.

Hydraulic cylinders are mechanical actuators that convert hydraulic fluid pressure into linear motion. They are used to lift, push, pull, or position loads in machines and equipment.

Hydraulic cylinders are found in excavators, forklifts, presses, tractors, cranes, and many other systems where controlled force is required.

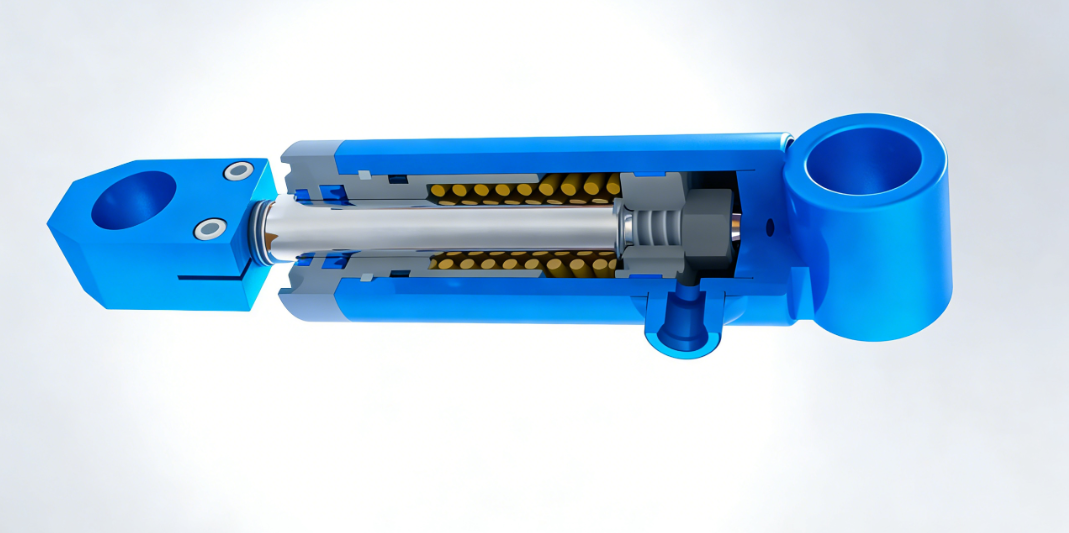

Single acting cylinders use hydraulic pressure to move the piston in one direction only. The return stroke is achieved by gravity, springs, or external force.

Single acting cylinders are often chosen for basic motion tasks where powered retraction is not required.

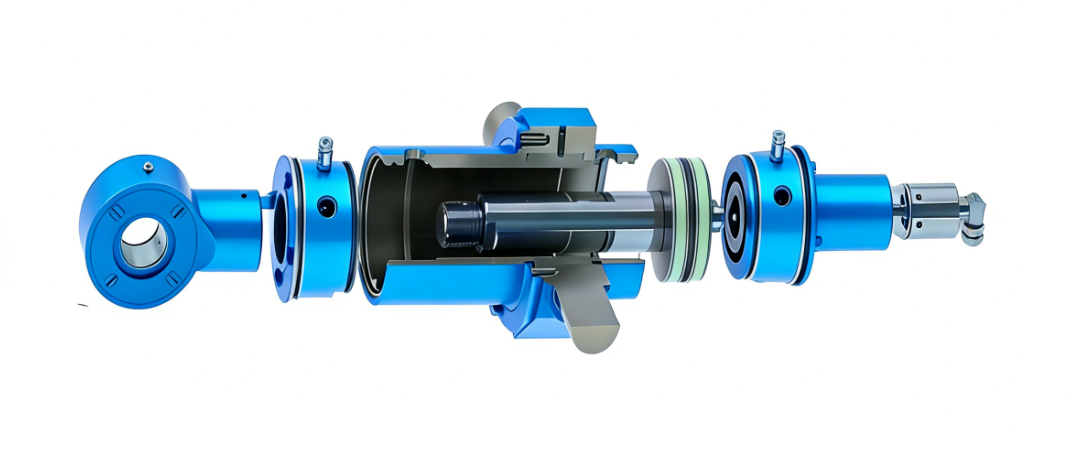

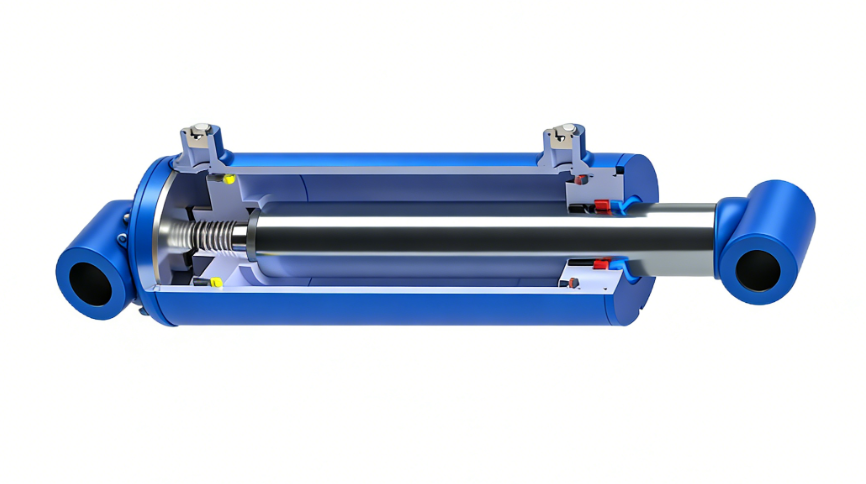

A double acting cylinder uses hydraulic pressure to move the piston in both extension and retraction directions.

Double acting cylinders are widely used in automated systems where accurate motion control is required.

Both types of hydraulic cylinders operate based on hydraulic pressure principles.

Excavators, loaders, and cranes use double acting cylinders for precise movement and control.

Tractors and harvesters use both single acting and double acting cylinders depending on the task.

Presses, automation systems, and machine tools use double acting cylinders for controlled positioning.

Forklifts and lifting platforms use hydraulic cylinders for lifting, tilting, and positioning loads.

When selecting a cylinder type, consider:

Single acting cylinders are suitable for simple lifting tasks, while double acting cylinders are preferred for precise and continuous motion.

Both cylinder types require:

Proper maintenance ensures reliable operation and long service life.

Single acting cylinders use hydraulic pressure in one direction, while double acting cylinders use pressure in both extension and retraction.

Single acting cylinders are commonly used in hydraulic jacks, lifting platforms, and simple lifting applications.

Double acting cylinders are used in construction machinery, industrial automation, and material handling equipment.

Yes, double acting cylinders usually cost more due to additional ports, seals, and hydraulic control requirements.

Yes. Manufacturers offer custom bore sizes, stroke lengths, mounting styles, and sealing options for both single and double acting cylinders.

The best type depends on the application. Single acting cylinders are suitable for basic tasks, while double acting cylinders are better for controlled and continuous motion.

Single acting and double acting hydraulic cylinders serve different purposes in industrial and mobile applications. Understanding their working principles, advantages, and applications helps buyers and engineers select the right solution for their systems.