Hydraulic systems continue to evolve across industrial machinery, construction equipment, material-handling systems, agriculture, and manufacturing. At the core of these systems is the hydraulic cylinder, a powerful linear actuator that transforms hydraulic energy into mechanical force. This 2026 comprehensive guide provides a clear answer to what is a hydraulic cylinder, how does a hydraulic cylinder work, and introduces cylinder parts, types, applications, and innovations.

A hydraulic cylinder is a mechanical actuator that creates linear motion and force by using pressurized hydraulic fluid. It is widely used in heavy-duty machinery because it provides high force, smooth motion control, and reliable performance under demanding conditions. From excavators to industrial presses, hydraulic cylinders remain essential components that enable powerful and precise movement.

Hydraulic cylinders operate based on Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions.

Here’s a basic overview of how a hydraulic cylinder works:

In single acting cylinders, hydraulic fluid powers movement in only one direction (usually extension), and the return is done by gravity or a spring.

In double acting hydraulic cylinders, hydraulic pressure is used for both extension and retraction, providing more precise and powerful control.

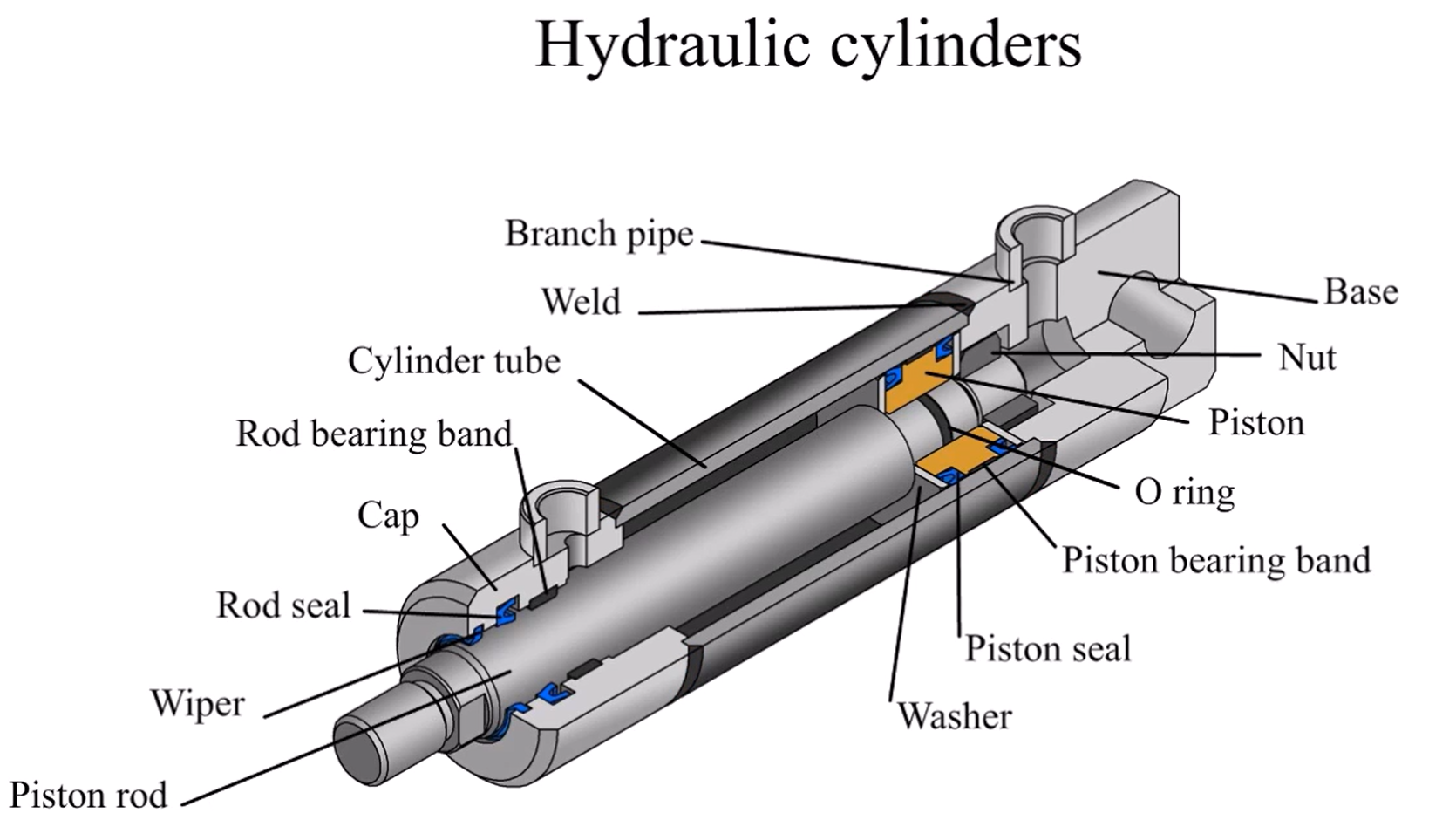

A hydraulic cylinder consists of several key components:

The outer body that holds the hydraulic fluid and supports internal pressure.

Separates the cylinder into pressure chambers and transfers force from fluid pressure.

Connects the piston to external machinery and delivers linear force.

Prevent fluid leakage and keep contaminants out of the cylinder.

Seal the cylinder barrel and provide structural support.

Allow hydraulic fluid to enter and exit the cylinder.

Such as clevis mounts, trunnions, and flanges, enabling installation onto machinery.

Different applications require different hydraulic cylinder designs. The most common types include:

Uses hydraulic pressure for one direction of motion. Simple, cost-effective, and ideal for lifting or pressing applications.

Uses hydraulic pressure for both extension and retraction. Essential for construction, industrial automation, and mobile equipment.

Feature a welded body for high strength and compact size. Common in mobile hydraulics, material handlers, and agricultural machinery.

Use high-strength tie rods to hold the cylinder together. Easy to assemble and service, popular in industrial machinery and factory equipment.

Tailored to special environments, stroke lengths, bore sizes, and mounting configurations. Used in aerospace, robotics, mining, offshore equipment, and specialized machinery.

Hydraulic cylinders play a critical role in almost every heavy-duty equipment category. They deliver reliable linear force for lifting, pushing, steering, stabilizing, and precise industrial control. Below are the key application sectors with expanded examples.

Hydraulic cylinders are fundamental in earthmoving and heavy-lifting construction machinery.

Typical equipment includes:

Welded cylinders and double acting hydraulic cylinders are widely used for boom lifting, chassis stabilization, steering, and high-pressure pushing.

In agriculture, hydraulic cylinders enable precise control for field operations and material handling.

Common equipment includes:

Hydraulic cylinders deliver motion for lifting, tilting, steering, and attachment control.

Factory and industrial equipment rely on tie rod cylinders and custom hydraulic designs for controlled, repeatable linear motion.

Applications include:

These cylinders ensure precise positioning, pressing force, and consistent cycle performance.

Hydraulic cylinders provide essential lifting force in warehouse and logistics systems.

Key equipment includes:

This category covers applications requiring reliable vertical or stable lifting power.

Marine and offshore environments demand corrosion-resistant hydraulic cylinders for continuous exposure to salt, moisture, and shock loads.

Typical systems include:

Custom hydraulic cylinders ensure long-term durability and precision under harsh conditions.

Many transportation systems depend on compact and durable hydraulic actuators.

Applications include:

Hydraulic cylinders provide lifting, tilting, and shock-absorbing performance.

High-precision hydraulic cylinders support mission-critical and safety-critical operations.

Examples include:

These cylinders often require custom engineering, extreme pressure resistance, and precise motion control.

As industries continue digital transformation, hydraulic cylinder technologies are evolving rapidly. Key trends include:

Real-time data on pressure, temperature, stroke position, and wear improves predictive maintenance and reduces downtime.

Low-friction components, advanced sealing systems, and optimized hydraulic paths increase overall efficiency.

Advanced materials such as nano-coatings enhance corrosion resistance and extend service life.

Cylinders integrated with electronic control systems deliver higher precision, ideal for robotics and autonomous machinery.

Recyclable metals, eco-hydraulic fluids, and sustainable production processes are becoming standard.

Hydraulic cylinders remain one of the most important components in modern industrial and mobile machinery. Understanding what a hydraulic cylinder is, how it works, and the differences between single acting, double acting, welded cylinders, tie rod cylinders, and custom hydraulic designs is essential for selecting the right solution. As industries move toward automation and smart machinery in 2026, hydraulic cylinders continue evolving with improved durability, precision, and digital intelligence. Their combination of raw power and advanced control ensures they will remain a key force-driving technology for decades to come.