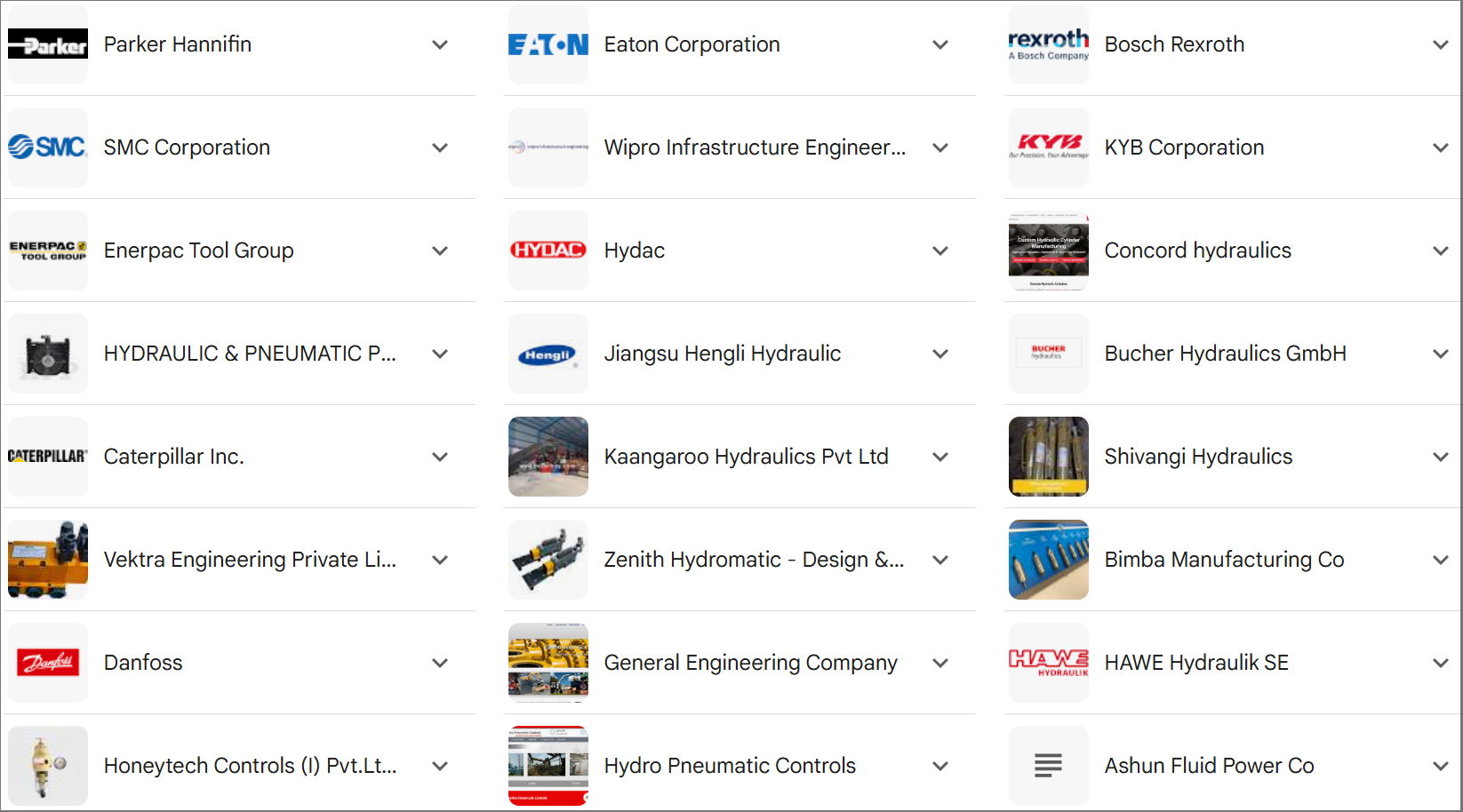

Below is a comprehensive overview of the world’s top 10 hydraulic cylinder manufacturers, selected based on market leadership, breadth of product portfolio, years of experience, innovation pedigree, and authoritative industry reports. These companies together shape the global hydraulic industry through their cutting-edge technologies, extensive distribution networks, and strong reputations for quality and reliability.

Parker Hannifin is consistently ranked as the leading global manufacturer of hydraulic cylinders, serving diversified industrial and aerospace markets with high-precision motion and control technologies. Its hydraulic cylinders are renowned for exceptional reliability and cost-effectiveness, underpinned by ISO-certified manufacturing and a comprehensive service network (MarketsandMarkets).

Parker offers the industry’s broadest NFPA-compliant cylinder lineup—from mill-type and tie-rod to telescopic and custom designs—ensuring an exact fit for any application.

Its proprietary TS-2000 seal and stepped-cushion technology deliver best-in-class leak protection and energy absorption, extending maintenance intervals and uptime.

Bosch Rexroth offers a broad range of mill-type and tie-rod hydraulic cylinders engineered to withstand the toughest industrial conditions, from machine tools to offshore applications. As an industry innovator, Rexroth continually enhances product safety and efficiency, meeting global regulations across all markets (Hydraulics Online).

Rexroth’s cylinders incorporate advanced safety features and electronic interfaces (IO-Link), enabling precise motion control and predictive maintenance in Industry 4.0 environments .

Engineered for extreme pressures and temperatures, their mill-type units use forged end caps and hardened piston rods for maximum durability in heavy-duty process and offshore applications .

Eaton’s hydraulic division delivers high-performance cylinders for mobile and industrial applications, emphasizing durability and energy efficiency. Market analysts cite Eaton among the top five global players due to its strategic mergers and technology investments that expand both capacity and innovation (MAXIMIZE MARKET RESEARCH).

Eaton leverages 100 years of hydraulics expertise to offer high-efficiency cylinders with low internal leakage and energy-saving seals, reducing power consumption in mobile and industrial systems.

Their global manufacturing footprint and modular design philosophy allow rapid customization and short lead times for OEMs across agriculture, construction, and mining.

Caterpillar manufactures OEM and aftermarket hydraulic cylinders tailored to heavy-equipment needs, offering five repair and replacement options (reseal to full rebuild) with guaranteed compatibility and rapid availability. Cat® cylinders are engineered for extreme jobsite conditions and backed by a global dealer network for uptime support (Cat.com).

Cat® cylinders are designed in tandem with their heavy-equipment platforms, ensuring drop-in fit, optimized rod-end geometries, and matched flow characteristics for peak machine performance .

The Cat Reman program offers turnkey rebuilds to OEM tolerances—backed by the same 12-month warranty as new units—minimizing downtime and total cost of ownership .

KYB—a Japanese company founded in 1919—is one of the world’s largest suppliers of hydraulic parts, including cylinders. Its “Mini-Motion Package” integrates motor, pump, valve, and cylinder into a compact unit, reflecting KYB’s drive for integration and leak-free design. With over a century of continuous technology improvements, KYB cylinders are prized for reliability in construction, agriculture, and material-handling applications (tvh.com).

KYB’s integrated “Mini-Motion Package” consolidates pump, motor, valve, and cylinder into a leak-free, compact unit—ideal for space-constrained mobile equipment .

With proprietary 4-lip sealing and high-chrome plating, KYB cylinders demonstrate twice the wear life of conventional designs in construction and material-handling markets .

Vickers by Danfoss has over 100 years of hydraulics expertise, offering tie-rod, welded, and extra-large custom cylinders used in offshore drilling, hydropower, and civil engineering. Their advanced Hydroclad™ laser-cladding technology extends piston-rod life in corrosive environments, underlining Danfoss’s focus on longevity and performance.

Vickers cylinders use laser-clad piston rods (Hydroclad™) that resist corrosion and abrasion, doubling service life in offshore and hydropower installations .

Their full-range ISO-rated portfolio—from small bore to extra-large custom actuators—coupled with global application engineering ensures turnkey delivery to any region.

HYDAC provides both standard and custom hydraulic cylinders, integrating sensor systems for real-time monitoring of position, pressure, and force. The company’s global engineering support and energy-efficient designs cater to mobile, industrial, and oil-and-gas sectors, making it a one-stop solution provider.

HYDAC embeds IoT-ready sensors (pressure, position, temperature) into its cylinders for live condition monitoring and predictive maintenance on oil-&-gas rigs and mobile fleets .

Their energy-efficient design minimizes internal leakage and heat generation, helping operators meet stringent emissions and carbon-reduction targets.

Poclain specializes in hydrostatic transmissions and cylinder systems for off-road machinery (construction, agriculture, mining). With manufacturing sites across Europe and North America, Poclain delivers tailored solutions enabling precise control and high reliability in demanding environments.

Poclain’s hydrostatic transmissions and cylinders are co-engineered for off-road machines, delivering seamless power transfer and optimized torque-steer characteristics in mining and earthmoving .

Their regional manufacturing hubs in Europe and North America enable rapid, low-cost customization to local market requirements .

Founded in 1904, Linde Hydraulics is a German-based leader in hydraulic pumps, motors, and cylinders for mobile and stationary equipment. Its axial-piston and bent-axis designs feature load-sensing technology and electronic controls, reflecting over a century of innovation and a strong after-sales service network (Wikipedia).

Linde’s bent-axis and axial-piston cylinder designs integrate load sensing and electro-hydraulic control valves for dynamic force adjustment and superior efficiency .

Over 115 years of R&D have honed seal technology and metal treatments that extend service life in high-duty-cycle mobile applications.

Enerpac is renowned for high-pressure hydraulic cylinders, jacks, and rams rated up to 10,000 psi and 1,000 tons. With a history dating back to 1910, Enerpac pioneered hydraulic tools and continues to lead with extensive configuration options, corrosion-resistant finishes, and robust safety certifications for industrial and lifting applications.

Each of these manufacturers distinguishes itself through a combination of technical excellence, comprehensive product lines, global service capabilities, and a proven track record in critical industries. Whether you require standard tie-rod cylinders, telescopic jacks, or fully integrated electrohydraulic actuators, these ten companies represent the most authoritative and innovative sources in the global hydraulic cylinder market.

Enerpac’s high-pressure cylinders (up to 10,000 psi, 1,000 ton capacity) feature gauge-set, safety-relief valves and rugged welded construction for critical lifting and jacking tasks .

Their configurable multi-stage telescopic jacks and hydraulic intensifiers provide bespoke solutions for heavy-lift maintenance in power plants and shipyards.