Hydraulic cylinders are crucial components in modern machinery, converting fluid power into linear motion. Among them, the double acting hydraulic cylinder stands out for its versatility and power. This guide explores what a double acting hydraulic cylinder is, how it works, and how it differs from single acting models. It also covers welded cylinders, tie rod cylinders, and answers common FAQs.

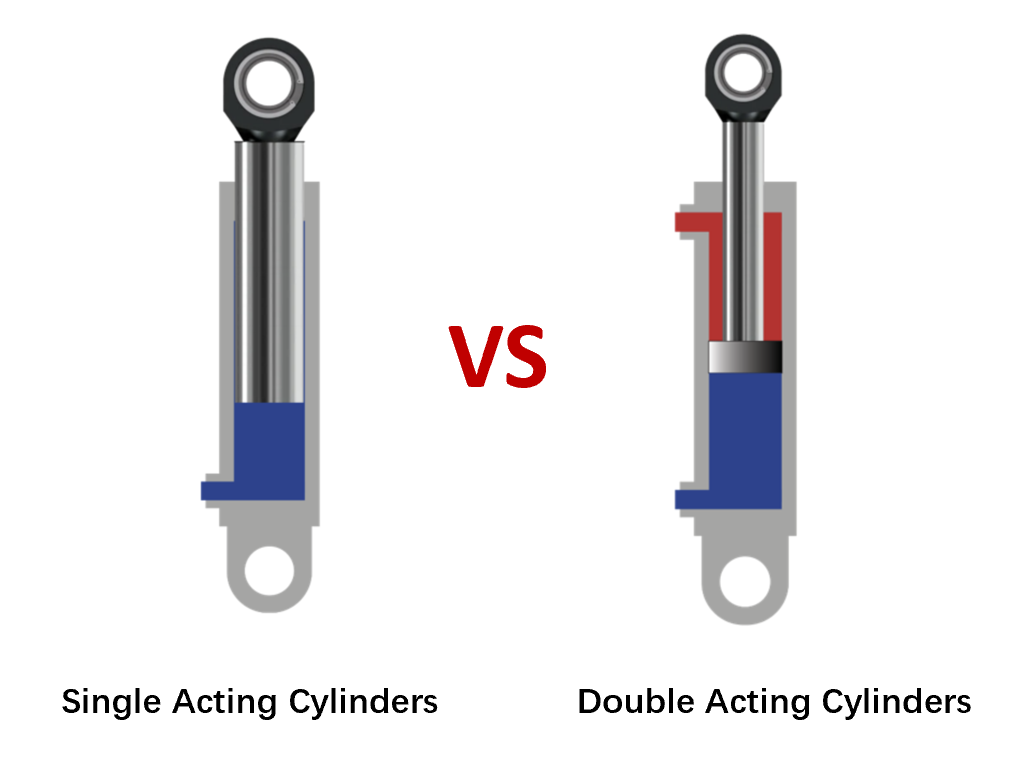

A double acting hydraulic cylinder is a type of acting hydraulic cylinder that generates force in both directions—extending and retracting the piston using hydraulic pressure. Unlike single acting cylinders, which only use pressure on one side, double acting cylinders feature two ports: one for extension and one for retraction.

This bidirectional design allows for controlled motion, higher efficiency, and consistent power output—making them ideal for machinery that performs lifting, pushing, or pulling tasks in construction, agriculture, and manufacturing industries.

Inside a double acting hydraulic cylinder, hydraulic fluid is pumped into one port to extend the piston, while the fluid from the other port returns to the tank. Reversing the flow retracts the piston. This continuous control of motion allows for smooth, precise operations in both directions.

The ability to deliver force during both strokes makes double acting cylinders essential for applications where reliability, precision, and power are required.

The main distinction lies in the direction of applied hydraulic pressure:

| Feature | Single Acting | Double Acting |

|---|---|---|

| Operation | Pressure in one direction | Pressure in both directions |

| Return Mechanism | Spring or gravity | Hydraulic fluid |

| Control | Simple | High precision |

| Applications | Lifting jacks, presses | Construction, automation, machinery |

While single acting designs are simpler and cost-effective, double acting cylinders provide greater control and flexibility for heavy-duty operations.

Welded cylinders feature welded end caps that create a compact, leak-resistant structure. They are perfect for high-pressure and heavy-duty environments like excavators, loaders, and cranes. Their durability and compact size make them a popular choice in mobile hydraulic systems.

Tie rod cylinders use threaded tie rods to hold end caps in place. This design simplifies disassembly and maintenance, making them ideal for factory and industrial machinery. They are typically used in manufacturing systems that require frequent servicing.

The versatility of double acting hydraulic cylinders makes them suitable for a wide range of uses:

Their durability and consistent force output make them the backbone of hydraulic power systems across industries.

Q1: What’s the main advantage of a double acting hydraulic cylinder?

It applies hydraulic force in both directions, providing better control and efficiency compared to single acting cylinders.

Q2: What’s the difference between welded and tie rod cylinders?

Welded cylinders are compact and strong for heavy-duty use, while tie rod cylinders are easier to maintain and service.

Q3: Can a double acting cylinder be used as a single acting one?

Yes, by using one port and venting the other, but this limits its efficiency and versatility.

Q4: Where are double acting cylinders used?

They are used in industrial machines, agricultural equipment, construction vehicles, and automation systems.

Q5: Are double acting cylinders more expensive?

Typically, yes. They include more components and deliver more performance, but the added cost is justified by their efficiency and power.

A double acting hydraulic cylinder is an essential component in any system that demands power and precision in both directions. Whether you choose welded cylinders for compact heavy-duty use or tie rod cylinders for easy maintenance, understanding how they differ from single acting models helps you make an informed choice for your machinery.